Stock Keeping Unit” or SKU for short. This is one term that you are likely to come across quite often in manufacturing and inventory management. Essentially, an SKU is a unique identifier. It is assigned to every product that a business sells. This identifier is used to track inventory levels, manage stock, and keep tabs on sales.

An SKU can be made up of a variety of different details. Such as manufacturer’s product code, the product size, color, and other distinguishing features. This way, businesses can easily differentiate between products that might look similar but are actually different.

One cannot oversate the importance of SKUs in manufacturing and inventory management. Without SKUs, businesses would have a much harder time. From tracking inventory levels to managing stock, and fulfilling customer orders. By assigning a unique identifier to each product, businesses can easily keep track of stock levels. It helps them know when to reorder products, and ensure that they always have the right products on hand to meet customer demand.

Taking a closer look at the different types of SKUs and how they are used in manufacturing and inventory management.

Different types of SKUs play unique roles in maximizing manufacturing efficiency:

Standard SKUs

- Standard products that can be sold individually or as part of bundles, collections, or assemblies.

- Helps maintain a clear inventory of individual products, facilitating accurate stock tracking and reordering processes.

Component SKUs

- Parts included in assemblies, bundles, and collections.

- Enable precise tracking of components needed for production, streamlining the assembly process and reducing waste.

Assembly SKUs

- Products that require assembly before shipment.

- Ensure all required components are available in the same facility, reducing delays and ensuring efficient assembly processes.

Bundle SKUs

- Products with associated SKUs that don’t need to be assembled together.

- Streamline the fulfillment process by grouping related items, enhancing order accuracy and customer satisfaction.

Collection SKUs

- Group of associated SKUs for marketing purposes to upsell or cross-sell.

- Encourage customers to buy complementary products, boosting sales and optimizing inventory turnover.

Virtual SKUs

- Non-physical SKUs like subscriptions or service fees.

- Allow diversification of product offerings without impacting physical inventory, contributing to increased revenue streams without added manufacturing costs.

Untracked SKUs

- SKUs loosely allocated to orders for faster routing.

- Ideal for promotions or giveaways where allocation precision is less critical, speeding up order processing and reducing fulfillment time.

By effectively managing these different SKU types, manufacturers can streamline production processes, reduce operational complexities, optimize inventory levels, and ultimately enhance overall manufacturing efficiency. Each SKU type serves a specific purpose in the manufacturing and sales processes, contributing to a more efficient and effective operation as a whole.

Reasons why SKUs are significant in the manufacturing industry:

Inventory management is a crucial aspect of a manufacturing business. One of the most important tools used in this process is the Stock Keeping Unit (SKU). SKUs are unique codes given to each item or product in a company’s inventory. They help in identifying and tracking products, making inventory management efficient. Here are some reasons why SKUs are significant in the manufacturing industry:

Efficient Tracking and Management

SKUs help manufacturers to track their inventory efficiently. By assigning a unique code to each product, businesses can quickly locate products in the warehouse, monitor their movement, and keep track of stock levels. This makes it easier to manage inventory and avoid stockouts or overstocking.

Demand Forecasting and Planning

SKUs also help manufacturers to forecast demand and plan production accordingly. By tracking sales data for each SKU, businesses can identify which products are popular and adjust their production schedules accordingly. This helps to minimize the risk of stockouts while reducing inventory carrying costs.

Optimized Inventory Control

With SKUs, manufacturers can optimize their inventory control processes. By using automated inventory management systems that are linked to SKUs, businesses can streamline their inventory management processes, reduce errors and improve accuracy, and save time and money.

Enhanced Customer Service

Finally, SKUs can help manufacturers to enhance their customer service. With SKUs, businesses can easily identify products and respond to customer inquiries quickly. This helps to improve customer satisfaction and build customer loyalty.

In summary, SKUs play a critical role in manufacturing. They help businesses to track their inventory efficiently, forecast demand, optimize inventory control, and enhance customer service. For manufacturers looking to improve their inventory management processes, implementing an SKU system is a smart solution.

Business Impact of SKU in Manufacturing

A. Operational Efficiency

SKU (Stock Keeping Unit) plays an essential role in managing the inventory of a manufacturing business. Effective management and utilization of SKU can lead to operational efficiency, which ultimately leads to better business performance. Here are some ways in which SKU impacts operational efficiency:

- Resource Utilization: SKU helps in effective resource utilization by providing the necessary data to plan and optimize production processes. With accurate SKU data, businesses can eliminate wastage, optimize inventory levels, and reduce lead times. This leads to more efficient use of resources, thereby reducing operational costs.

- Customer Service: The availability of the right product at the right time is crucial in meeting customer demand and providing excellent customer service. SKU helps in tracking the inventory levels of each product, which enables businesses to ensure adequate stock availability. This, in turn, leads to better customer satisfaction and retention.

- Business Planning: SKU provides valuable insights into sales trends and product performance, helping businesses to plan their production and sales strategies more efficiently. This helps businesses to optimize their operations and improve their bottom line.

B. Significance of Accurate SKU Forecasting in Driving Operational Excellence

Accurate SKU forecasting is crucial in driving operational excellence. Here are some ways in which accurate SKU forecasting impacts operational excellence:

- Supply Chain Optimization: Accurate SKU forecasting helps businesses to optimize their supply chain by ensuring that they have the right products in the right quantities at the right time. This leads to reduced lead times, improved order fulfillment, and better customer satisfaction.

- Cost Reduction: Accurate SKU forecasting helps businesses to reduce costs by optimizing inventory levels, reducing wastage, and eliminating stockouts. This leads to more efficient use of resources and reduced operational costs.

Challenges in SKU Management

SKU management can be a challenging task for businesses, especially when it comes to managing product variants, ensuring data accuracy, and dealing with the time-consuming nature of the process.

Product Variants: One of the biggest challenges in SKU management is dealing with product variants. With multiple product variations and attributes, it can be difficult to keep track of each SKU. This can result in confusion and errors, which can impact the business’s bottom line.

Data Accuracy: Another significant challenge is ensuring data accuracy. With a large number of SKUs to manage, it can be easy to make mistakes in data entry or product descriptions. This can lead to incorrect product information being displayed on the website, which can result in customer dissatisfaction and lost sales.

Time-consuming: Finally, managing SKUs can be a time-consuming process. It requires constant monitoring and updating of product information, which can take up valuable time that could be better spent on other business tasks. This can also lead to delays in getting products to market, which can impact the business’s revenue.

Despite these challenges, businesses can overcome them by implementing effective SKU management strategies. This includes investing in technology that automates the process and ensures data accuracy, as well as streamlining the workflow to make it less time-consuming. By doing so, businesses can optimize their SKU management process and ensure the successful growth of their business.

Qritrim AI Solutions for SKU Management

When it comes to managing inventory, businesses face a number of challenges such as balancing supply and demand, minimizing stockouts, and maximizing profitability. Fortunately, with the help of AI-powered tools, businesses can now leverage advanced analytics and automation to optimize their inventory management processes.

AI-based SKU Classification: One of the key areas where AI can be applied is in SKU classification. By using machine learning algorithms, businesses can automatically categorize their products based on various attributes such as size, color, material, and price. This enables them to better understand their inventory and make informed decisions about how to allocate resources.

SKU Demand Forecasting: Another important area where AI can be used is in demand forecasting. By analyzing historical sales data and external factors such as seasonality, weather, and promotions, businesses can predict future demand for their products with a high degree of accuracy. This helps them to optimize their inventory levels, reduce stockouts, and improve customer satisfaction.

SKU Optimization: In addition to SKU classification and demand forecasting, AI can also be used to optimize inventory levels. By setting dynamic safety stock levels, businesses can ensure that they always have enough inventory on hand to meet demand while avoiding overstocking. This helps to minimize waste, reduce costs, and improve overall efficiency.

AI-assisted Inventory Management: AI-powered tools can also assist with inventory management by providing real-time insights into product performance, identifying slow-moving items, and recommending actions to optimize inventory levels. This not only helps businesses to reduce costs and improve profitability, but also enhances their ability to meet customer demand and stay competitive in today’s fast-paced market.

For businesses looking to optimize their inventory management processes, Qritrim AI solutions and the Qi platform stand out as robust tools for SKU forecasting needs. These advanced AI-powered solutions provide a comprehensive range of features, including sophisticated machine learning algorithms, real-time data analysis capabilities, and actionable insights for accurate demand forecasting. By leveraging these tools, businesses can streamline their inventory operations, improve stock management, minimize costs, and enhance overall operational efficiency. Qritrim AI solutions and the Qi platform offer a seamless and integrated approach to SKU forecasting, empowering businesses to make informed decisions, meet customer demands effectively, and stay ahead in today’s competitive market landscape.

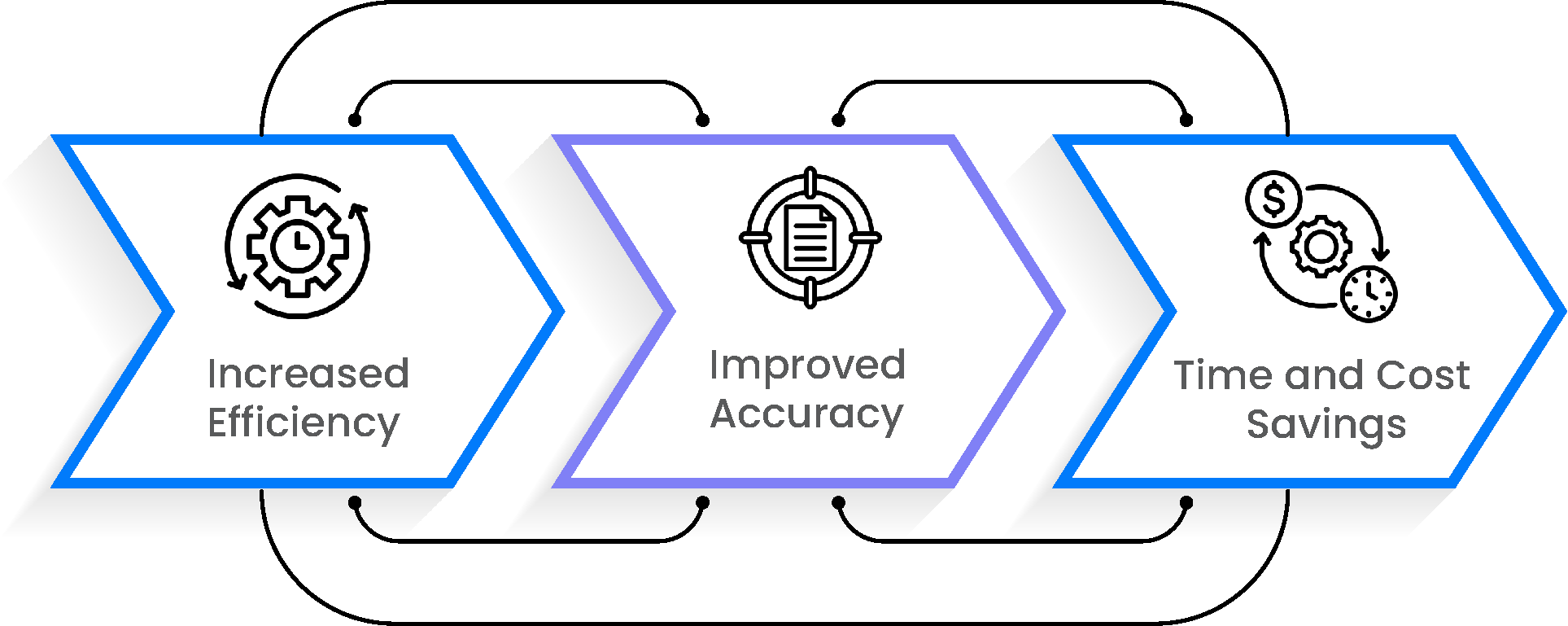

Advantages of Using AI in Business

Artificial intelligence (AI) has come a long way in recent years and has the potential to revolutionize the way businesses operate. By harnessing the power of AI, businesses can gain a competitive edge, save time and money, and improve efficiency and accuracy. Here are some of the key advantages of using AI in business:

- Increased Efficiency: One of the biggest advantages of using AI is increased efficiency. AI-powered systems can automate routine tasks, freeing up employees to focus on more complex tasks that require human intervention. This can help reduce the risk of errors and improve overall productivity.

- Improved Accuracy: AI systems are also highly accurate, which can be invaluable in industries such as healthcare and finance where errors can have serious consequences. By using AI-powered systems to analyze data and make decisions, businesses can reduce the risk of errors and ensure that decisions are based on accurate information.

- Time and Cost Savings: By automating tasks and improving accuracy, AI can help businesses save time and money. For example, AI-powered chatbots can handle customer queries 24/7, reducing the need for human customer service agents. This can help businesses save on staffing costs while also providing customers with faster and more efficient service.

Overall, AI has the potential to transform the way businesses operate, providing them with a competitive edge and helping them to achieve their goals more effectively. By embracing AI and investing in the right technology, businesses can reap the benefits of increased efficiency, improved accuracy, and time and cost savings.

Drive operational efficiency with efficient inventory tracking

Stock Keeping Units (SKUs) play a pivotal role in manufacturing and inventory management, enabling businesses to efficiently track inventory, forecast demand, optimize inventory control, and enhance customer service. The unique identifiers assigned to each product variant streamline operations, improve resource utilization, and ultimately drive operational efficiency. However, challenges such as managing product variants, ensuring data accuracy, and the time-consuming nature of SKU management can pose obstacles for businesses.

Looking ahead, the future of SKU forecasting holds promising advancements, with AI solutions poised to revolutionize SKU management processes. Qritrim, with its Artificial Domain Intelligence (ADI) solutions and the Qi platform, offers tailored AI models and continuous learning capabilities to enhance SKU forecasting accuracy. By leveraging machine learning techniques, incorporating exogenous variables in forecasting, and exploring advanced modeling approaches, Qritrim empowers businesses to optimize inventory levels, reduce costs, and efficiently meet customer demand.

For those seeking robust SKU forecast implementation, Qritrim’s AI solutions provide deep domain expertise, real-time data processing, and AI-assisted inventory management for proactive decision-making. By utilizing Qritrim’s AI capabilities, businesses can transform their SKU forecasting strategies, drive operational excellence, and stay competitive in the dynamic manufacturing landscape.