Precision, efficiency, and safety are not just goals – they’re absolute imperatives in the evolving landscape of manufacturing. Electrical diagrams are essential for modern industrial operations as they form the foundation of electrical systems. While ensuring seamless operations, compliance with safety standards, and rapid issue resolution they stand as the backbone of manufacturing excellence. Keeping accurate and up-to-date records is essential for maintaining the integrity of information.

However, the challenges faced by manufacturing industries are not insignificant. It is a fact that in many manufacturing setups, critical electrical information remains locked in outdated. Forever they are kept as and virtually unusable hard copies of diagrams. Very often as time passes these diagrams are neglected. They become obsolet and become as barriers to progress. They not only lack the real-time accuracy needed in today’s fast-paced world but also introduce the potential for costly errors and operational disruptions.

The presssing challenge here is the difference between old documentation and the dynamic industrial landscape. Manufacturers have long relied on intuition rather than precise information when dealing with outdated electrical diagrams.

But now, it’s time for change. Our Electrical Diagram Extraction (EDE) Solution steps in as the beacon of transformation that the manufacturing industry urgently needs. We recognize the dilemma – the discrepancy between legacy documentation and the evolving present.

The Role of Electrical Diagrams in Manufacturing

Ensuring safety, operational efficiency, and compliance with industry standards in manufacturing electrical diagrams play a pivotal role. For understanding, maintaining, and troubleshooting electrical systems within industrial setups these diagrams form the basis . However, relying on outdated hard copies of diagrams presents several drawbacks and challenges that hinder modern manufacturing operations.

- Drawbacks of Outdated Hard Copies: Outdated hard copies of electrical diagrams introduces numerous challenges. The limit the accessibility, lack of real-time updates, and the potential for errors due to obsolete information and inhibit proactive decision-making, troubleshooting, and overall maintenance of electrical systems.

- Ensuring Operational Efficiency: To maintain the operational efficiency of manufacturing systems accurate and up-to-date electrical diagrams are important.

- Outdated hard copies often lack real-time updates and modifications, leading to inefficiencies and potential disruptions in the production process. Inaccurate diagrams can result in incorrect decision-making, hindering the overall efficiency of manufacturing operations.

- Safety and Compliance: Compliance with safety standards and regulations is of paramount importance in industrial settings. Outdated electrical diagrams may not accurately represent the current state of electrical systems, posing safety risks and non-compliance with industry standards. The reliance on obsolete hard copies for critical electrical information can compromise workplace safety and regulatory adherence.

EDE Solution addresses these challenges by transitioning from traditional hard copies to digital representations. It enables manufacturers to revolutionize their approach to electrical diagram management and optimization within the manufacturing landscape.

Bridging the Gap with EDE Solution

QRITRIM’s Electrical Diagram Extraction (EDE) Solution stands out as a groundbreaking initiative in the manufacturing industry. This transformative solution leverages advance AI technology to bridge the gap between legacy documentation and the need for dynamic, updated information within manufacturing environments. It addresses the longstanding challenge of outdated and inaccessible hard copies of electrical diagrams.

The EDE Solution acts as a catalyst for change. By enabling manufacturing companies to transition from traditional, paper-based diagrams to interactive, digital representations this solution revamps the way electrical systems are managed and maintained. By extracting and digitizing information from outdated hard copies this not only streamlines operations but also enhances decision-making processes based on accurate and up-to-date data.

Working of the EDE Solution

The EDE Solution operates through a meticulous process that revolutionizes the management of electrical diagrams in manufacturing settings. Here’s a step-by-step breakdown of how the EDE Solution extracts, digitizes, and updates electrical diagrams:

- Data Extraction: The process commences with scanning old and obsolete hard copies of electrical diagrams. The EDE Solution employs advanced data extraction algorithms to accurately capture the information presented in these documents.

- Digitization: Following data extraction, the solution transforms the scanned data into digitized formats. Through Optical Character Recognition (OCR) and AI-based computer vision technologies, traditional or non-digital diagrams are converted into machine-readable versions.

- Update and Modification: One of the key features of the EDE Solution is its capability to empower users to update and modify the digital representations of electrical diagrams. Real-time updates can be made to ensure that the diagrams reflect the current state of electrical systems.

- Interactive Features: The digital representations are not static; they offer interactive features that allow users to engage with and manipulate the diagrams as needed. This interactivity enhances the usability of the diagrams for troubleshooting, maintenance, and decision-making.

By emphasizing real-time updates and incorporating interactive elements, the EDE Solution enables manufacturing companies to move beyond obsolete hard copies and embrace a more efficient and future-ready approach to electrical diagram management. With QRITRIM’s EDE Solution, manufacturing operations are poised for enhanced productivity, streamlined workflows, and informed decision-making based on accurate and dynamic electrical system representations.

Benefits of Implementing the EDE Solution

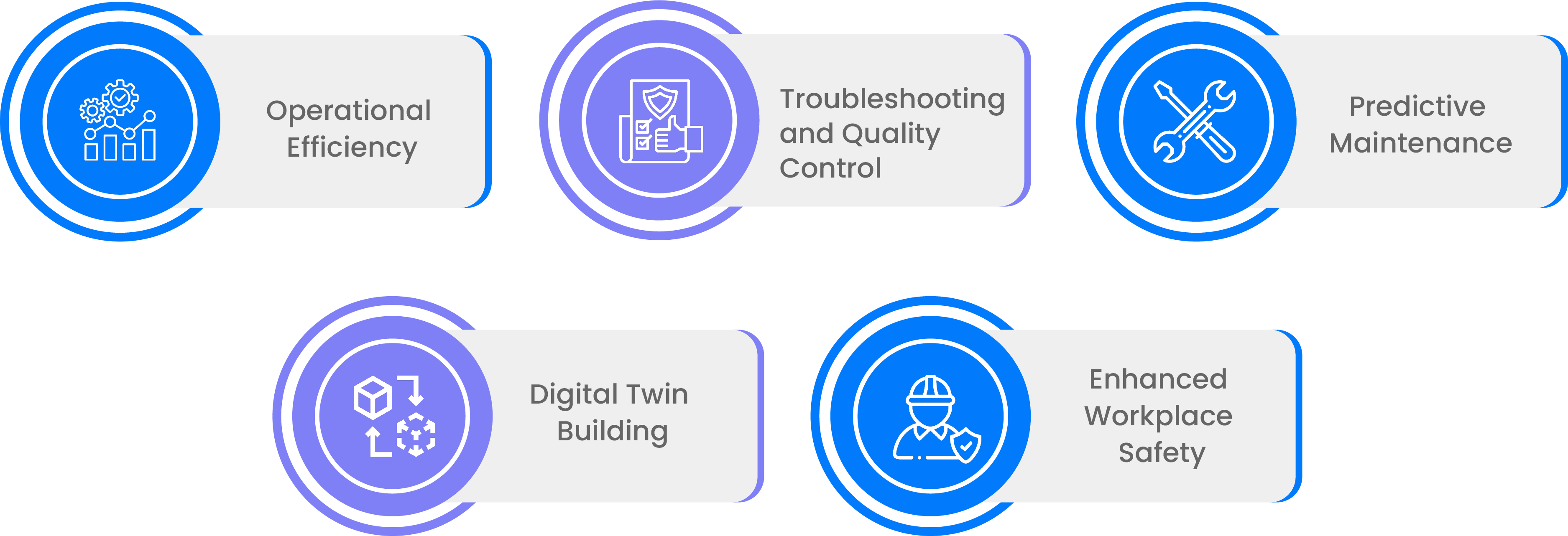

Implementing QRITRIM’s Electrical Diagram Extraction (EDE) Solution presents a multitude of advantages for manufacturing industries, enhancing operational efficiency, troubleshooting methods, and quality control.

- Operational Efficiency: Accurate and up-to-date documentation achieved through the EDE Solution equips manufacturing operations with real-time accuracy, ensuring that electrical diagrams always reflect the current state of electrical systems. This seamless transition from paper to digital diagrams streamlines workflows, reducing operational downtime through quick issue identification and resolution. The result is enhanced equipment management and improved operational efficiency.

- Troubleshooting and Quality Control: The transition to digital diagrams facilitates streamlined troubleshooting and problem identification, ensuring a smooth workflow. Additionally, the EDE Solution enhances quality standards by verifying and bolstering them through meticulous component audits. The digital representations evolve into audit-ready documentation, which eases regulatory inspections and quality control checks.

- Predictive Maintenance: Implementing QRITRIM’s EDE Solution enables manufacturing facilities to move away from unplanned downtime and towards a predictive maintenance approach. Leveraging the knowledge about component information, connections, and historical performance, the solution allows for the prediction of maintenance needs, preventing costly operational disruptions.

- Digital Twin Building: With the advanced capabilities for digital twin building offered by the EDE Solution, manufacturing facilities can simulate, analyze, and monitor physical facilities or equipment like never before. This ability to create digital replicas empowers more accurate and effective analysis of the physical systems.

- Enhanced Workplace Safety: Accurate and up-to-date electrical diagrams reduce the risk of accidents and enhance workplace safety. Employees can confidently work with precise information, ensuring their safety in the manufacturing environment.

Unique Approach of QRITRIM

QRITRIM’s unique approach to Electrical Diagram Extraction (EDE) Solution encompasses cutting-edge technology, advanced data extraction algorithms, and an intuitive user interface, along with a focus on workflow integration, support, training, and mechanisms for continuous improvement.

- Cutting-Edge Technology: QRITRIM leverages cutting-edge technology, including Optical Character Recognition (OCR) and AI-based computer vision, to accurately convert traditional or legacy electrical schematics and diagrams, even those in paper or non-digital formats, into accessible, machine-readable versions.

- Data Extraction Algorithms: With advanced data extraction algorithms, the EDE Solution not only digitizes the diagrams but transforms data in a way that makes it highly functional for manufacturing operations, focusing on precision and functionality.

- Intuitive User Interface: The solution incorporates an intuitive user interface, making it easy for manufacturing teams to access, analyze, modify, and utilize the digitalized electrical diagrams, ensuring user-friendliness and successful technology adoption.

- Workflow Integration and Support: QRITRIM ensures a smooth transition by integrating the digitalized electrical diagrams directly into manufacturing processes, enhancing troubleshooting, maintenance, quality control, and automation aspects.

- Training and Continuous Improvement: The approach goes beyond implementation, offering comprehensive support and training to ensure that manufacturing teams fully benefit from the EDE solution. It also includes mechanisms for ongoing management and real-time updates to keep the digital diagrams accurate and up-to-date.

By embracing QRITRIM’s cutting-edge technology and comprehensive approach to electrical diagram management, manufacturing industries can elevate their operations, leveraging real-time accuracy, predictive maintenance, and enhanced workplace safety to propel their industry into the future.

Why Choose QRITRIM for EDE Needs

When it comes to selecting a partner for Electrical Diagram Extraction (EDE) needs, QRITRIM stands out as a frontrunner due to several key strengths that set it apart from the competition.

- Expertise in Industry 4.0: QRITRIM’s profound expertise in Industry 4.0 positions it as a reliable and knowledgeable partner for manufacturing industries. Understanding the unique challenges faced by these industries, QRITRIM has crafted its EDE solution specifically to address these challenges effectively, ensuring that it is tailored to meet the evolving needs of the industry.

- Comprehensive Approach: QRITRIM doesn’t just offer a one-time digitization service. Its EDE solution encompasses a comprehensive approach to electrical diagram management. From initial data ingestion to real-time analysis, modifications, and ongoing management, QRITRIM creates a dynamic cycle that continually enhances the electrical systems of the manufacturing setups it serves.

- Technical Assistance and Support: By integrating EDE with IoT devices and sensors, QRITRIM offers real-time monitoring and support, enabling quick issue identification and resolution. This capability helps manufacturing setups avoid unplanned downtime, with QRITRIM’s support team always ready to assist in achieving maximum efficiency and operational excellence.

Additionally, QRITRIM’s integration of AI and ML technologies, customization, scalability, and long-term benefits for manufacturers make it a formidable choice for EDE needs in the manufacturing industry.

Conclusion

In conclusion, QRITRIM’s Electrical Diagram Extraction (EDE) Solution stands as the catalyst for revolutionizing manufacturing operations. By bridging the gap between legacy documentation and the dynamic present, the EDE Solution transforms outdated, static diagrams into interactive, real-time representations that empower manufacturing industry to achieve operational excellence, safety, and compliance.

We encourage readers to consider QRITRIM’s EDE Solution for their manufacturing industry needs. The solution is not only a means to digitize outdated diagrams but represents a roadmap to a new era of manufacturing, where precision, efficiency, and safety are the cornerstones of every decision and operation. Embrace a future-proofing solution that leverages cutting-edge technology and a comprehensive, supportive approach by choosing QRITRIM for your EDE needs.