Raw Material Traceability Automation

INTRODUCTION

The importance of raw material traceability cannot be overstated in manufacturing. Every component that goes into a product has a story, from its origin to its final destination. However, manual processes for tracking and managing these raw materials pose significant challenges impacting efficiency, accuracy, and compliance.

CHALLENGES IN MANUAL PROCESSES

Recognizing these challenges, Qritrim has developed a groundbreaking solution – Raw Material Traceability Automation. This innovative system leverages advanced technologies to automate the entire process of raw material tracking, from label reading to real-time documentation and check-in updates. By eliminating manual intervention, our solution addresses the shortcomings of traditional methods. It unlocks a new level of efficiency and accuracy in inventory management.

QRITRIM'S RAW MATERIAL TRACEABILITY AUTOMATION SOLUTION

Our solution is based on the smooth integration of state-of-the-art technologies including real-time data processing, optical character recognition (OCR), and customizable rules and warnings. This integration enables automated label reading. Instant documentation of crucial information and timely updates to inventory check-ins. The result is a streamlined and error-free process that optimizes resource utilization, reduces costs, and ensures compliance with regulatory standards.

The Raw Material Traceability Automation system from Qritrim can completely change the way manufacturers handle raw materials. With better data quality, operational efficiency, and regulatory compliance, our technology helps organisations remain competitive in the quick-paced manufacturing world of today.

Key Features

Real-time Documentation

Using real-time data processing capabilities, our system instantly captures and documents essential information from raw material labels. Ensures records are accurate and up to date at all times.

Check-in Updates

Seamlessly update inventory check-ins in real-time as raw materials move through the manufacturing process, providing immediate visibility into stock levels and movement.

Automated Label Reading

Employing advanced optical character recognition (OCR) technology the solution automatically reads and interprets labels on raw materials. Eliminates the need for manual data entry and reduces the risk of errors.

Integration Capabilities

Our solution is designed to integrate seamlessly with existing inventory management systems, ERP software, and databases, enabling smooth data flow and enhanced collaboration across departments.

Customizable Rules and Alerts

Tailor the system to your specific requirements with customizable rules and alerts. Set thresholds for quality control, compliance checks, and supply chain optimizations, and receive alerts for actionable insights.

Historical Tracking

Maintain a comprehensive history of raw material movements and transactions for traceability and audit purposes. Access historical data for analysis, reporting, and compliance verification.

OPTIMIZING RAW MATERIAL TRACEABILITY IN A PHARMACEUTICAL MANUFACTURING FACILITY

In a pharmaceutical manufacturing facility, ensuring the traceability and quality of raw materials is paramount to meet regulatory standards and maintain product integrity. Let’s delve into a typical use case scenario to illustrate how Qritrim’s Raw Material Traceability Automation solution revolutionizes this process.

As raw materials arrive at the facility, our solution automatically reads and interprets the labels using OCR technology. This eliminates manual errors and speeds up the receiving process.

Crucial information such as batch numbers, expiry dates, and supplier details is instantly captured and documented in the system, ensuring accurate record-keeping and compliance.

The system seamlessly updates inventory check-ins in real time as raw materials move through production stages. This provides immediate visibility into stock levels and enables proactive decision-making.

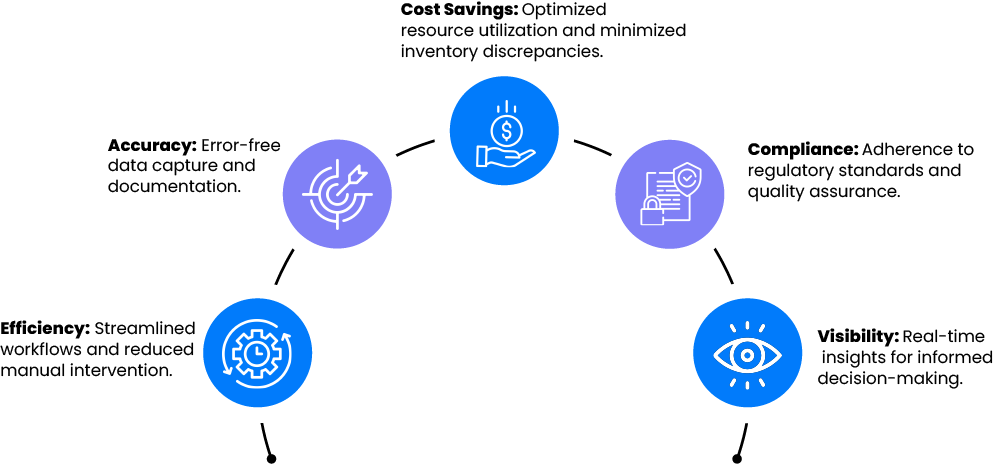

Advantages and Outcomes

Enhanced Efficiency

By automating raw material traceability processes, the facility experiences a significant reduction in manual labor and processing time, leading to streamlined workflows and increased productivity.

Regulatory Compliance

The solution ensures compliance with regulatory requirements such as FDA guidelines by maintaining accurate records, facilitating audits, and demonstrating adherence to quality standards.

Improved Quality Control

Real-time documentation and check-in updates enable proactive quality control measures. Any discrepancies or issues can be identified and addressed promptly, ensuring high-quality.

Cost Savings

The automation of traceability processes leads to cost savings through optimized resource utilization, reduced labor costs, and minimized inventory discrepancies.

Enhanced Visibility

Real-time visibility into raw material movements and inventory status allows for better inventory management, demand forecasting, and supply chain optimization.

ACHIEVE OPERATIONAL EXCELLENCE, ENSURE PRODUCT QUALITY, AND DRIVE BUSINESS GROWTH WITH CONFIDENCE.

The Raw Material Traceability Automation system from Qritrim completely transforms quality control and inventory management procedures in production settings. Our system provides unmatched advantages by utilising real-time data processing, customisable rules, and extensive automation capabilities: