Accuracy of inspection systems highly depends on the quality and diversity of training data. The variations, defects, and anomalies you want the system to detect should all be present in the training data. It is essential to have diverse datasets and wide range of products with conditions varying from normal to potential defects otherwise insufficient or biased training data leads to inaccuracies and false positives.

Different inspection tasks require different algorithms or in combinations. While you may have complex algorithms it is essential to fine-tune them. Based on the industry or domain there could be many characteristics to consider for the type of defect you want to detect. Hence the models may require extensive training and optimization for desired results.

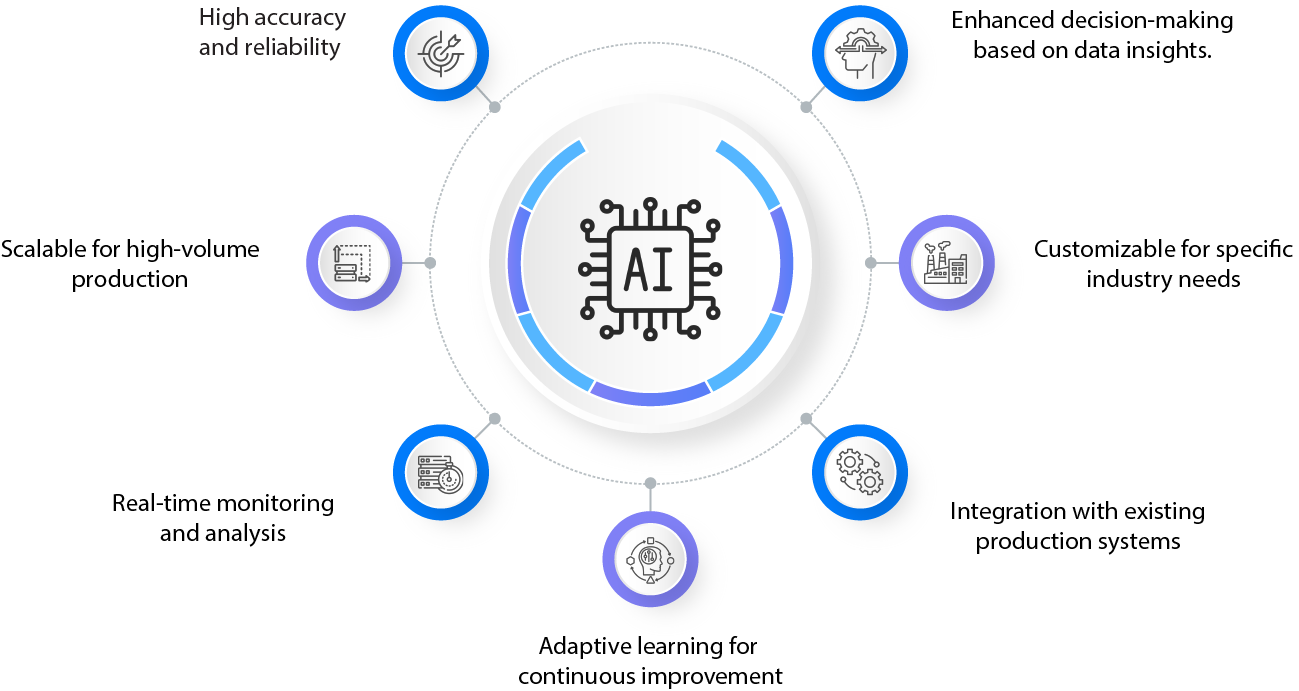

Synchronization of AI-based inspection systems within product lines, equipment, and workflows is essential to facilitate real-time data capture and analysis. Seamless integration enables immediate feedback and disciplinary actions based on inspection results improving quality control.

Real-time processing capabilities are critical for timely and proactive quality inspection. This minimizes delays in the identification of quality issues and prevents potential risks further along the production line.