Making a place as an industry leader for any manufacturer is heavily dependent on the quality of the product that is produced. Not necessarily, quality checks are only important when the product is ready to go to market. To maintain quality, the check should start with the raw materials and continue at all stages of the production process. If so, for any manufacturer, the constraints will be the time and resources needed to run the quality check.

No doubt we have all automated machine to handle such tasks. And yes automation is no new thing in manufacturing industry.

However, new advanced technologies are.

Using advanced technologies for the automation of tasks by machines has become one of the biggest technological revolutions in this field.

Artificial intelligence and Deep Learning are accelerating these daily advances. Object detection is one such advancement.

Object Detection is a key component of Computer Vision which involves locating specific objects from images. This is an essential aspect of manufacturing automation.

What Is Object Detection?

Object detection is a field within computer vision focusing on recognizing and localizing objects in images or videos. The goal of object detection technology is to detect objects with particular attributes in digital images or videos using machine learning. Object detection is often used as an initial step for item recognition, where we first locate objects and then apply recognition models to identify specific elements.

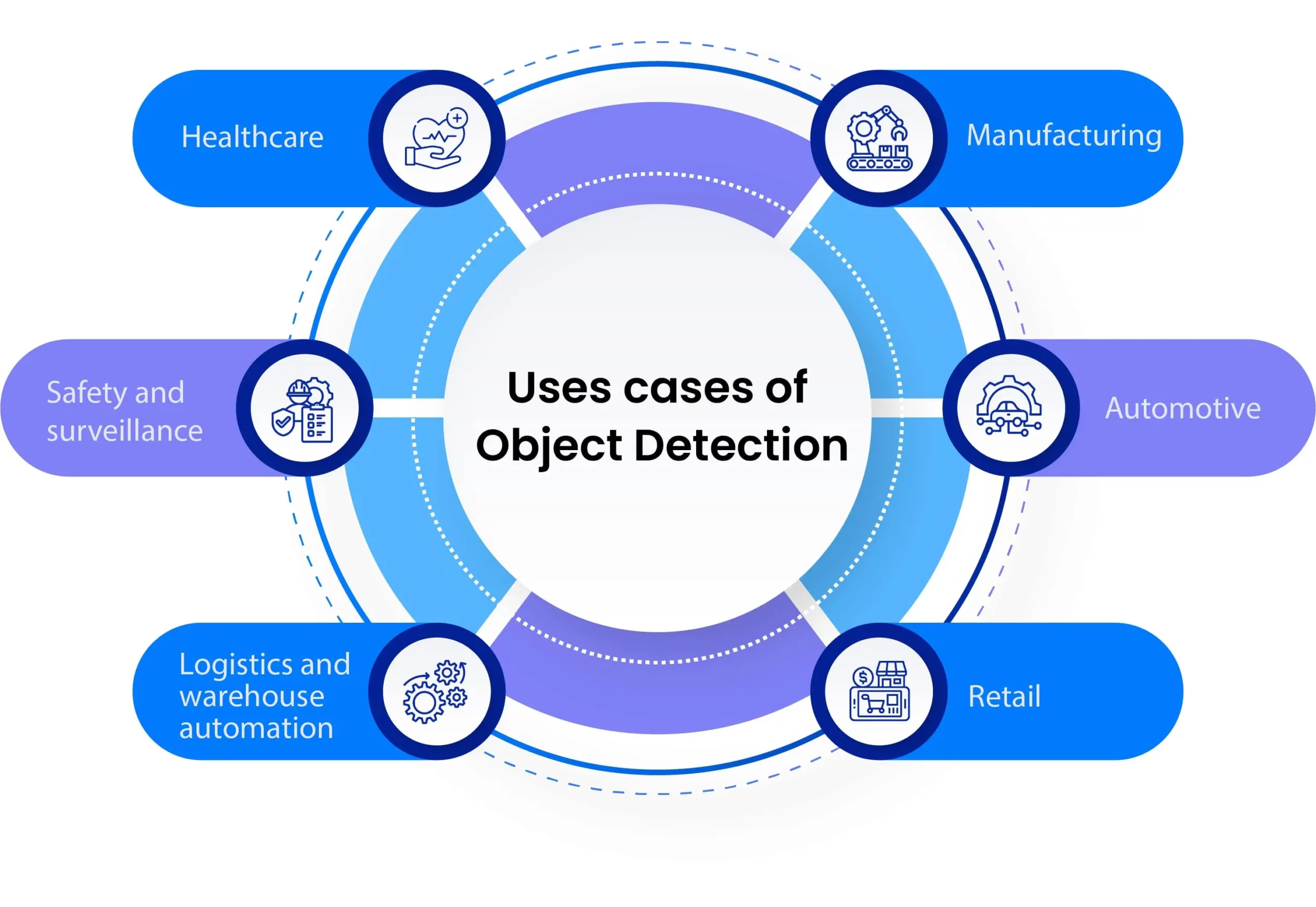

Object Detection Use Cases

Object detection is a core task of AI-powered solutions. Mainly used for visual inspection, warehouse automation, inventory management, security, and more. Below are some object detections use cases that are successfully implemented across industries. Object detection is a crucial aspect of AI-powered solutions for a variety of purposes. Visual inspection, inventory management, security, and warehouse automation are the best examples. The following are some successful object detections use cases implemented across different industries. First, let’s see the uses of object detection in different industries, and then discuss the use cases specific to the manufacturing industry.

Object detection is a core task of AI-powered solutions. Mainly used for visual inspection, warehouse automation, inventory management, security, and more. Below are some object detections use cases that are successfully implemented across industries. Object detection is a crucial aspect of AI-powered solutions for a variety of purposes. Visual inspection, inventory management, security, and warehouse automation are the best examples. The following are some successful object detections use cases implemented across different industries. First, let’s see the uses of object detection in different industries, and then discuss the use cases specific to the manufacturing industry.

Manufacturing: The aspect of automating numerous manufacturing processes, specifically in quality assurance, inventory management, assembly line, and sorting Object detection is essential. Identification of defects, counting and locating objects, and enhancing inventory accuracy by minimizing human error and time spent can all be achieved using machine learning algorithms.

Automotive: Today, in various transportation systems to improve safety, efficiency, and traffic management, machine learning has been integrated for instance, it is used in self-driving cars to detect and classify objects such as pedestrians, other vehicles. Also detects obstacles on the road. Object recognition is also used to detect and count vehicles, which helps in traffic analysis and detecting cars that stop on highways or crossroads. Optimizing traffic flows in cities to reduce congestion and enhance road safety is all achieved through machine learning algorithms.

Retail: Object detection is a useful technology that helps in identifying and tracking SKUs (Stock Keeping Units) by analyzing and comparing images of the shelves with the ideal state. This technology is integrated with computer vision techniques that are embedded in the hardware, which helps in reducing waiting time in retail stores, tracking customer interactions with the products, and automating the delivery process. It is a powerful tool that can greatly improve the efficiency of the retail industry.

Healthcare: Object detection is a method used to analyze medical images such as CT scans, MRIs, and X-rays. This technique is widely employed in cancer screening to identify high-risk patients, detect abnormalities, and even provide surgical assistance. The application of object detection and recognition to aid medical examinations for telehealth is a novel trend that has the potential to revolutionize healthcare delivery to patients.

Safety and Surveillance: Object detection technology has a wide range of applications, including in video surveillance systems that can detect people and recognize faces. These systems are developed using machine learning algorithms and are specifically designed for biometric authentication and remote surveillance. Interestingly, this technology has also been used for suicide prevention purposes.

Logistics and warehouse automation: Object detection models can be used for defect detection, inventory management, quality control, and automation of supply chain management. AI-powered logistics solutions replace manual scanning by using object detection models instead of barcode detection.

Now let us see how this technology can be applied to manufacturing practices. The manufacturing industry is constantly evolving, and the integration of AI technology has the potential to make it more cost-effective and efficient. AI-powered systems can be applied to various manufacturing practices, such as quality management, inventory management, sorting, assembly line, and custom object detection.

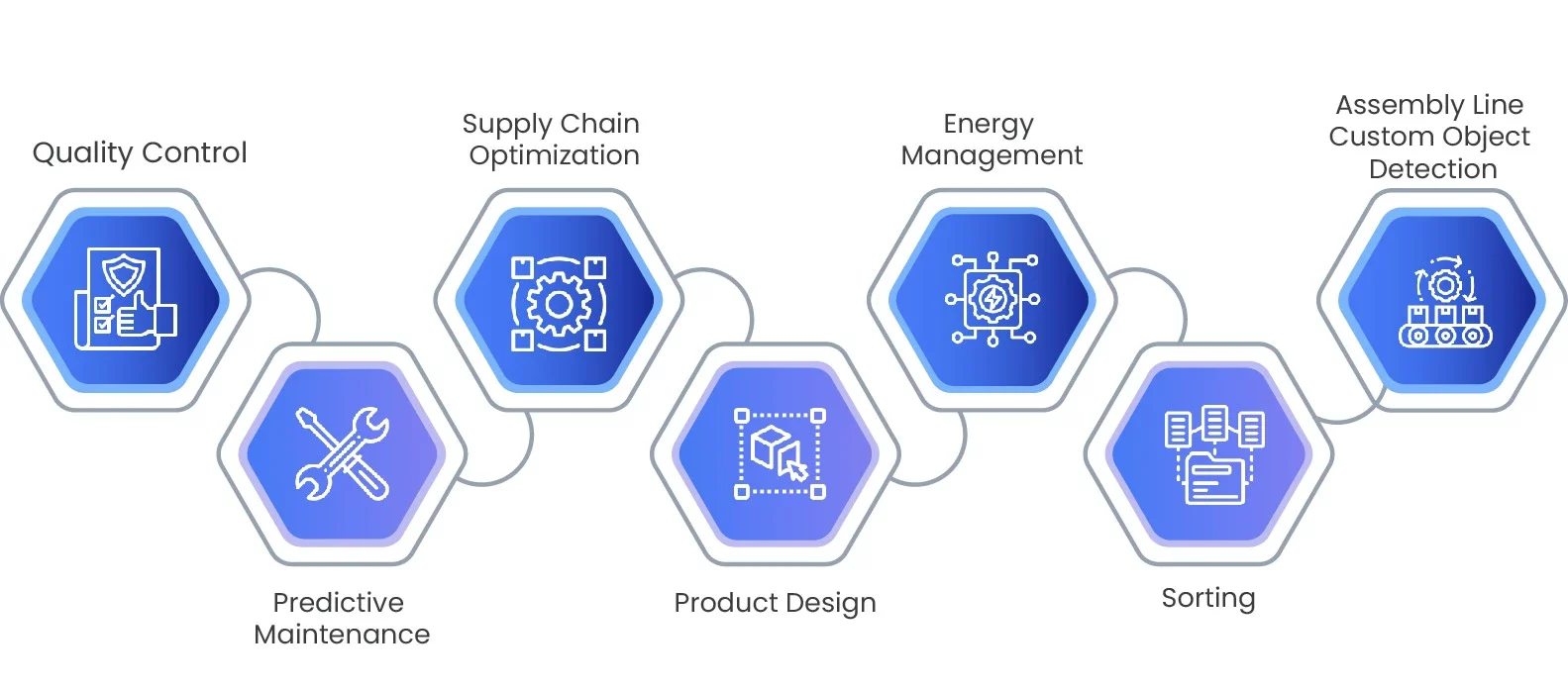

Uses Cases Of Object Detection In Manufacturing Industry

- Quality Control: AI-powered systems can be used to detect defects in manufacturing processes, allowing for real-time adjustments to be made to prevent further defects and improve overall quality control.

- Predictive Maintenance: AI algorithms can analyze sensor data and predict when machines are likely to fail, allowing for preventative maintenance to be scheduled before a breakdown occurs, minimizing downtime and maintenance costs.

- Supply Chain Optimization: AI can be used to optimize supply chains, making it possible to better manage inventory levels, reduce waste, and ensure that products are delivered to customers in a timely and cost-effective manner.

- Product Design: AI can assist in product design by analyzing customer feedback and identifying trends and patterns, allowing manufacturers to create products that better meet customer needs and preferences.

- Energy Management: AI-powered systems can be used to optimize energy consumption in manufacturing facilities, reducing costs and environmental impact.

- Sorting: AI-powered systems can be used to sort products and materials more efficiently, reducing labor costs and improving accuracy. By analyzing data from sensors and cameras, AI algorithms can identify and sort items based on various criteria such as size, shape, color, and weight.

- Assembly Line Custom Object Detection: AI-powered systems can be used to detect defects or anomalies in manufacturing processes. By analyzing images or videos from cameras placed along the assembly line, AI algorithms can identify objects that do not meet certain specifications and alert workers to take corrective actions.

The implementation of AI in manufacturing can bring about significant improvements, including enhanced operational efficiency, cost reduction, and better quality of products and services. AI-powered solutions can provide manufacturers with data-driven insights to identify and address potential issues before they turn into major problems. Object detection using AI can help in real-time defect detection, reducing downtime and maintenance costs by predicting equipment failures. Additionally, AI can optimize supply chains by identifying patterns and trends, and assist in product design by analyzing customer feedback. With AI-powered solutions, manufacturers can achieve better efficiency, cost savings, and improved quality of products and services.

At Qritrim, we have developed an advanced Object Detection model tailored to the specific needs of manufacturing industries. Our model utilizes state-of-the-art machine learning algorithms and computer vision techniques to enhance quality control, streamline inventory management, optimize assembly line processes, and improve overall operational efficiency. With our Object Detection model, manufacturers can automate tasks, reduce errors, and make data-driven decisions to drive continuous improvement and maintain a competitive edge in today’s rapidly evolving market landscape.

Are you ready to redefine manufacturing excellence? Take the first step towards a more efficient and competitive future. To explore how our Object Detection model can transform your manufacturing operations contact us now.